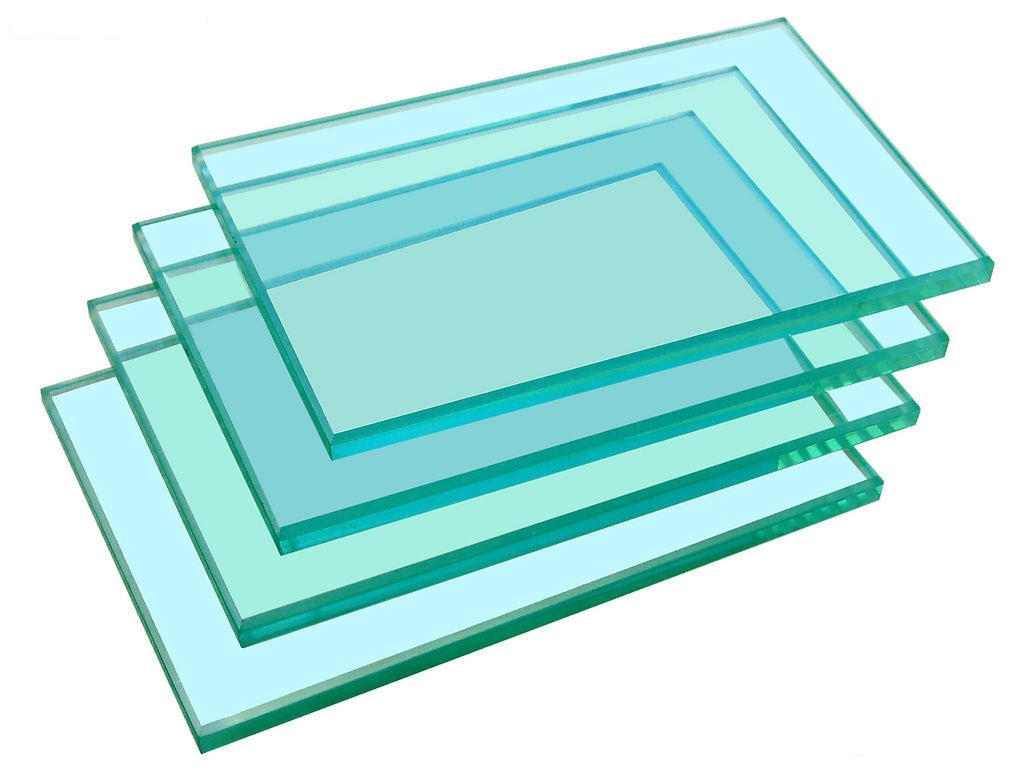

Glass has undoubtedly secured its position in the world of architecture and interior designing, having no competitors to challenge its fluid aesthetic appeal and innovative functionalities. But, the supreme evolution of glass to as we know it today had its origins in a special type of glass, known as float, annealed, or even flat glass.

Invented in 1959, this glass is made using some of the most abundant raw materials found on the earth’s surface like silica sand, limestone, soda ash, dolomite, and glass cullet.

How Is Float Glass Made?

Float glass is made by melting the aforementioned items in a 1600°C preheated furnace and then pouring them onto a shallow bath of molten tin. This molten glass is allowed to cool on the tin by spreading itself out to form a flat surface. After cooling, the glass pane solidifies and flattens out evenly, which is why it is occasionally also called flat glass. Rollers run on top the glass’ surface to pull and stretch it out, in case a thinner finish is needed.

The cooling process is not as straightforward as it sounds. Molten glass is slowly brought down from the fierce temperature of 600°C to about 100°C. After the glass has cooled down, it is trimmed to remove any uneven or excess glass. These spare glass shavings are used as cullet for newer batches. The whole process is recyclable and highly sustainable, with almost nothing going to waste.

The process of cooling glass down in a controlled and monitored manner is called annealing. Annealing awards the glass pane higher density and a higher refractive index. Tinted float glass is manufactured by pouring colouring agents during the melting process. Iron, cobalt and selenium are used to make green, grey, bronze and blue tints.

Applications of Flat Glass

Flat glass or Annealed glass is commonly used for commercial as well as residential purposes. Let us look at its applications in detail –

Residential Real Estate

Flat glass is commonly used for small windows that do not need to withstand high temperatures or pressures. Float glass can shatter into sharp shards on impact, which is why it is mostly made to undergo heat strengthening, tempering, insulation, lamination, and other such processes to improve and increase its applications. An annealed glass pane that has further gone through a strengthening process has multifarious applications.

Commercial Glazing

Flat glass has become quite popular for constructing the exterior of commercial spaces. It gives the dwellers an impression of being outside, along with a sense of openness. All stories begin with float glass. This foundational glass pane goes through a heat toughening treatment before it is installed in office buildings, restaurants, retail outlets, display cases, etc.

Five Characteristics of Flat Glass

Since flat glass boasts superior clarity, it allows for a higher degree of light to pass through it. Using windows made of flat glass allows a healthy amount of natural light to permeate into your homes or offices and makes them bright and cheery.

Available in Several Tints

If you love glass but your home or office is in direct line of solar glare, fret not! Flat glass is available in several tints and shades, with an ability to produce a diverse range of translucencies. You can choose among bronze, grey, green, blue, etc. Tinted annealed glass allows a comfortable amount of natural light to shower through but acts as a solid barrier between you and the glare to keep you safe from ultraviolet (UV) rays as well infrared (IR) rays.

Easily Mouldable

Since this type of glass can be cut, drilled, polished and fileted after fabrication, it can be customised to precisely match your design sensibilities, before putting it through the irreversible processes of tempering or lamination.

Eco-friendly

The process of manufacturing flat glass leaves no waste and is environment-friendly. All the extra glass shards that get trimmed off go back in the furnace to be recycled. This makes the entire process sustainable.

Available in Multiple Thickness Options

Flat glass can be made to order in various dimensions and densities, which is awarding it with new and unique applications. For example, with modern advancements, manufacturers have now started producing ultra-thin float glass that has applications in televisions, computer, and mobile phone hardware.

Easy to Maintain

Flat glass does not collect a lot of dust or grime and stays placid for years on end. However, it is always a good idea to care for your door and window glass panels to ensure that they stay dust-free. Wipe your float glass windows once a week with a soft, damp cloth. Use a microfiber cloth for best results. You can also use soapy water to wipe any grime or debris off its surface. Make sure that you leave no soap residue on the panes towards the end of the cleaning process, as this will attract more dirt.

The Bottom Line

Looking for flat glass for your next project? Turn to AIS Glass for all your glass-related needs. We are a subsidiary of the leading glass manufacturer in India – Asahi India Glass Limited – and provide end-to-end glass-related services for over three decades. Rely on our team of professionally-trained technicians to help you select the right glass for your home or office.

So, what are you waiting for? Get in touch with us today!